Energy Conversion¶

Direct heat with industrial Heat Pump¶

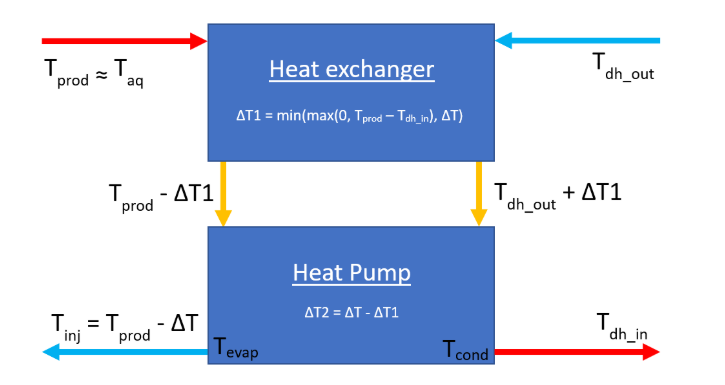

Below is a schematic representation of the direct heat production with an industrial heat pump system, which effectively allows to increase outlet temperature for a district heating network, relative to the geothermal source production temperature

Figure 2: a schematic representation of the system. On the left is the primary circuit of geothermal brine with temperature Tprod, assumed equal to the aquifer temperature Taq. The temperature is first lowered by amount ΔT1 in the heat exchanger. Next, the temperature is lowered by amount ΔT2 in the heat pump to the injection temperature Tinj. On the right hand side is the district heating network. The cool water returning from the network at temperature Tdh_out is first heated in the heat exchanger to Tdh_out + ΔT1, and then by the heatpump to the heat network inlet temperature Tdh_in. It is assumed that condenser and evaporator temperatures of the heatpump are respectively 3°C lower and higher than the source and outlet temperature of the heat pump

The COP of the heat pump is given by the following equation:

COPhp = ηrel (Tdh_out + 273.1 + 3) / (Tdh_out - Tinj + 6)

nrel is set to 0.6 and is the relative efficiency of the heat pump as a fraction of the Carnot efficiency.

The resulting Power is the net power output of the geothermal plant, which is the geothermal power output

corrected for the conversion efficiency and any parasitic power losses.

For direct heat it does not include added heat in the heatpump from the compressor. The reason not to include this is to account for geothermal energy only. This setting can be changed by setting

Proposed parameters are the following:

| parameter | symbol | value | unit |

|---|---|---|---|

| use heat pump | HPuse | True | bool |

| HP application target temperature is Tdh_in | HPapp | True | bool |

| target district heat outlet temperature | Tdh_in | 80 | °C |

| minimum aquifer production temperature | Tminprod | 40 | °C |

| maximum cooling temperature for reinjection relative to reservoir (ΔT) | ΔTmax | 40-200 | °C |

| minimum injection temperature (clips cooling) | Tmininj | 15 | °C |

| injection (return) temperature (interpreted as Tdh_out) | Treturn | 40 | °C |

| Conversion efficiency | η | 1 | - |

| Parasitic power needs for conversion process (fraction of net power) | epara | 0 | - |

| annual load hours | Hload | 6000 | hour |

| Capex Base expense for the geothermal Doublet | CAPEXbase | 3 | million€ |

| Capex Variable (including heat exchanger) for the geothermal Doublet | CAPEXother,var | 300 | €/kW |

| base Opex for the geothermal doublet | OPEXbase | 0 | k€ |

| annual Opex per unit geothermal net power | OPEXpower | 50 | €/kW |

| Additional opex per unit heat | OPEXheat,var | 0 | €/kWh |

| Heat Pump Capex Variable | CAPEXhp,var | 600 | €/kW |

| Heat Pump annual Opex per unit power | OPEXhp | 10 | €/kW |

| Include electric consumption of HP compressor in output power | EHPinclude | False | bool |